In history, mankind had researched volcano’s lava erupting over the forest and applied it into charcoal manufacturing. Among all types of charcoal, coconut shell is one of the most favorable and eco-friendly product, which is made from sustainable natural resources.

Coconut shell charcoal is the by-product of pyrolysis process which involves burning coconut shells in a limited supply of oxygen in order to carbonize it first. After that, coconut shell charcoal is crushed into powder and mixed with botanical adhesive to manufacture different shapes and size of charcoal briquettes. Drying and packaging are final steps to carry out before launching coconut shell charcoal.

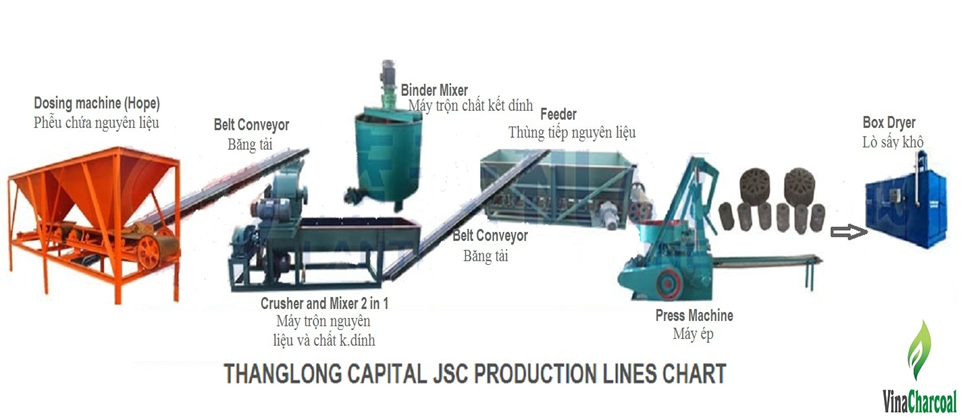

1. Production process overview

Manufacturing process includes a variety of phases but it can be shortened in 2 main stages:

.png)

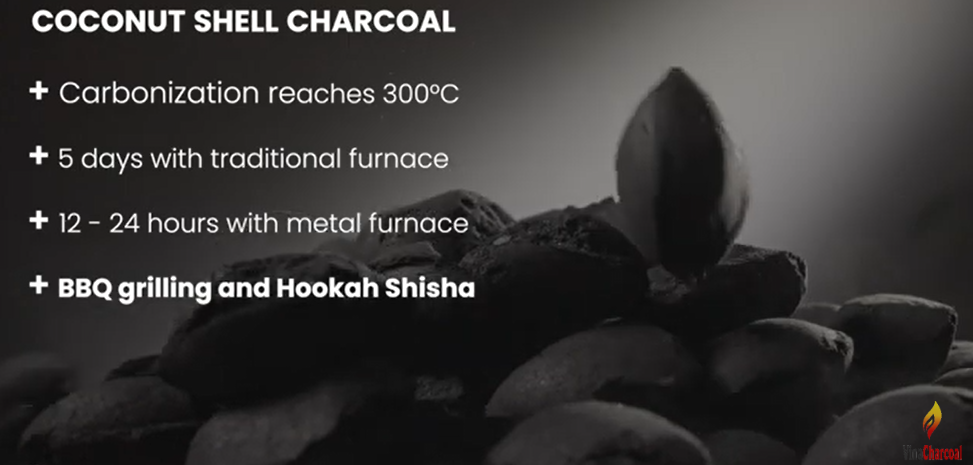

2. Coconut Shell Manufacturing Process

To making coconut briquette, firstly we need to produce coconut shell charcoal through carbonization processing ; is the same technique of black wood charcoal procesing. Carbonizing in traditional furnace, it takes about 5 days at 300 degree point, if using metal furnace it takes 12 - 24 hours. Coconut shell charcoal is used in many fields: actived carbon, filltered & purified water, deodorization, gold - filtering, and detoxification,... and pressing briquette with 2 applications: BBQ and Shisha.

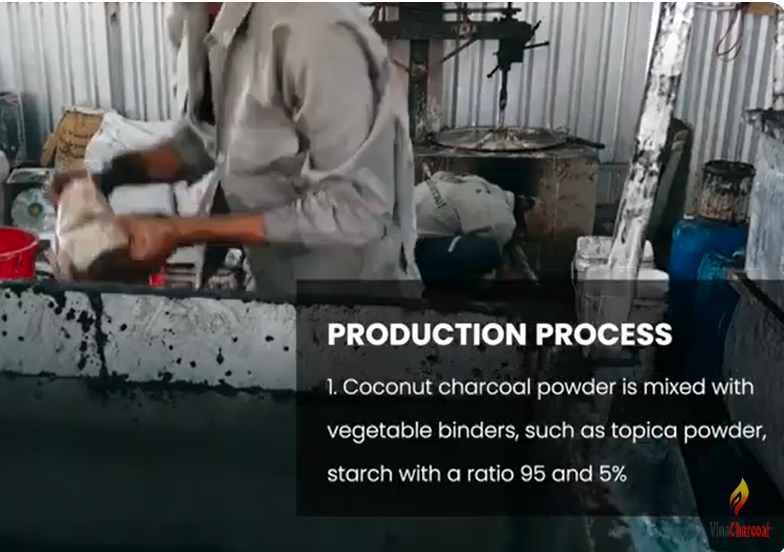

3. Coconut Charcoal Briquette

General techniques:

Ingredients: Coconut charcoal powder is mixed with vegetable binders, such as topica powder, starch. They are very safe for health, both of the materials are mix very well with a ratio 95 and 5% and moisture 25%.

Then the mixed materials are put into the pressing system. There are two briquette pressing techniques : Hydraulic pressing and screw extrusion. Charcoal briquettes are then put into the drying kilns at a temperature of 100 degrees for about 24- 48 hours to get the moistures below 8%. The next process is cooling and packaging .

Shisha charcoal: This kind is a premium coconut charcoal, all most of them are produced by screw extrusion technique. Coconut charcoal powder for shisha are grilled from 100% coconut shell charcoal, it called pure coconutshell powder. Then they combined topica adhensives with 1 - 3 % and moisture 25 %.

|

|

|

4. Vinacharcoal Coconut Briquette Charcoal

Coconut shell charcoal is increasingly popular because of its own advantages. It is completely eco-friendly, safe to use and easy to inflame plus its high level of calorific value, as a whole coconut shell charcoal becomes widely used in food industry. Vinacharcoal supply to the international market with 2 main products:

- Coconut Briquette Charcoal For BBQ

- Coconut Briquette Charcoal For Shisha

We are enthusiastic about the possibility of collaborating with wholesalers and are confident that our products will add significant value to your portfolio. For any inquiries or to request samples, feel free to contact us directly via WhatsApp at +84823659659 or email us at charcoal4@thaloca.com.