Basic principle: Due to human research and application from the discovery of charcoal caused by volcanic lava eruptions covering the former forests. The difference is the product of the burning process of wood sticks (the fresher the better the better) in an incomplete anaerobic environment, separating the carbon from the organic root components in the tree.

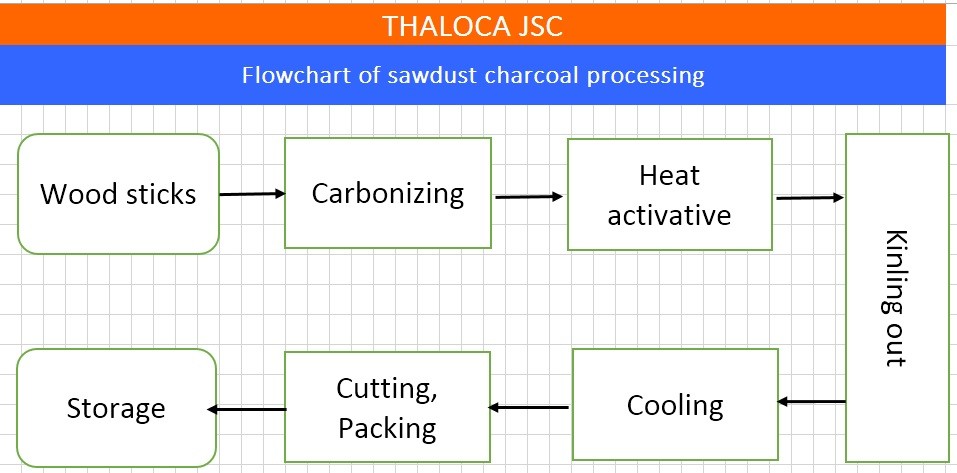

1. Production process:

1. Production process:

When the wood stick have ignited, the furnace door will be gradually closed so that the wood stick burn in an anaerobic environment, until all the wood stick in the furnace are completely charred, it will switch to the charcoal making process by opening the furnace door to supply oxygen.

When the wood stick have ignited, the furnace door will be gradually closed so that the wood stick burn in an anaerobic environment, until all the wood stick in the furnace are completely charred, it will switch to the charcoal making process by opening the furnace door to supply oxygen.

- Charoal tunneling stage: 6-8 days and the furnace temperature is 500-700˚C (Black charoal stage)

- Charcoal smelting stage: 5-7 hours and the furnace temperature 900-1100˚C (White charoal stage)

- Cooling phase: 2-3 days, charoal temperature is below 40˚C

3. You can refer to the kiln system:

Charoal kiln system, furnaces are often built continuously, smoke can collect smoke concentrated on the top. There are 2 sizes of universal furnaces for 5 tons or 8 tons of firewood. In addition, there are iron furnaces or electric furnaces, but they are not popular because the current quality is not equal to that of masonry kilns and the electricity costs are also higher, charcoal efficiency is from 8-12%.